26 Pictures Analyzing Pallet Management at Businesses

26 Pictures Analyzing Pallet Management at Businesses

Buy Pallets, Sell Pallets, and Find FREE Pallets at Repalletize

Click here to search the map

Share Your Pallet Buying And Recycling Experience With Your Friends

Businesses with Pallets for Sale Need Pallet Management Programs

I am sure you have heard that pallet management programs are important when buying pallets or selling pallets. But we could not find much research about why it was important. So we put our data scientist to work to find out what companies are doing with their pallets. We are happy to share 26 pictures and analyzes of what is happing in pallet management programs. Some pallet management programs are good, some are bad, and some are plain ugly.

7 Essentials For Pallet Management

Identifying Pallet Types

- There are many types of pallets. The most common types of pallets are block and stringer wood pallets. Other common pallets are plastic pallets, pressed wood pallets, metal pallets, spill containment pallets, cardboard pallets, corrugated pallets, EUR pallets, Euro pallets, and display pallets.

Sorting Pallets by Size

- Pallets should be sorted by size. The common standard pallet size is the GMA 48x40-inch pallet. Pallets also come in sizes like 42x42-inch, 48x48-inch, 40x48-inch, 48x42-inch, 48x45-inch, 44x44-inch, 36x36-inch, and 48x20-inch.

Sorting Pallets by Material

- You should always sort pallets by the material they are made out of. Wood and plastic pallets should be keep in separate stacks. Once you learn how to sort pallets you can offer pallets for sale.

Grading Pallets

- Sorting pallets by grade is important when selling pallets. A very high quality pallet that has bright wood is called an A-Grade pallet . A reusable pallet that may have a few repairs and some wood discoloration is called a B-Grade pallet. A pallet that has broken or missing boards are called tear down pallets or pallet cores and should be separated for repairs.

Repairing Pallets

- Pallets that have broken boards should be taken out of the pallet supply and repaired. Repairing pallets is important for pallet management. Pallets that are missing boards should not be used and sent to the repair shop. Broken pallets can damage the goods or products you are storing or shipping.

Pallet Stacking

- Stacking pallets correctly requires a little bid of oversight and management. Pallets that are the same size, same grade, and same material, and same type should be stacked together. This will prevent pallets from falling over. Stacking pallets correctly can prevent employee injuries.

Pallet Pricing

- Stacking pallets correctly will help you get better pricing when you sale your pallets. Offering pallets for sale that have been sorted, graded, and stacked correctly will get you the highest prices.

2 Essentials For Gaylord Boxes and Super Sack Management

Stacking Gaylord Boxes - Stacking Gaylord boxes for sale or bulk boxes is similar to pallets. The boxes should be sorted by size, type, and condition.

Stacking Super Sacks

- Stacking Super Sacks or bulk bags is similar to pallets. They should be sorted by size, type, and condition. Stacking bulk bags correctly will help you sale super sacks for higher prices.

The Good Bad and Ugly Pallet Management Programs

1.

Analysis:

This company has sorted pallets by size. You can see that similar sized pallets are stacked together. You can also see that larger pallets are placed on the bottom of stacks to prevent pallets from tipping over. This company appears to get pallets that are built differently so stacking them by type is a little difficult because there are not many standard pallets.

Recommendation:

This company should continue to sort pallets by size. If the company starts receiving similar pallet types such as stringers and block pallets those should start to be sorted out by size and type. By recycling pallets companies can reduce waste.

2.

Analysis:

This company has done a good job with sorting the 48x40-inch pallets they receive. This company has sorted pallets by size and appears that the condition is similar. You can see that similar sized pallets are stacked together. The company has also sorted by type, as all the pallets are stringer pallets and no block pallets are in the stacks. The pallets are also stacked at a safe height and a good height for loading onto a truck.

Recommendation:

This company should continue to sort pallets by size, type, and condition. The company should start too look for A-Grade pallets that could be separated out in another stack.

3.

Analysis:

This company should not store broken pallets at their dock and in the warehouse. This is a safety hazard for employees. Loose boards can cause tripping hazards for employees. Broken pallets can have exposed nails that can puncture and cut employees. This operation could be in violation of OSHA rules.

Recommendation:

These pallets are beyond repair so the company should start a collecting broken pallets in a container to send to a mulching operation, bio-fuel plant, or other recycling operation to prevent landfill disposal. Gloves, steel toed boots, eye protection, and hardhats should be worn to clean up this mess. These broken pallets could also have the wood reclaimed to make pallet bars or other DIY pallet projects.

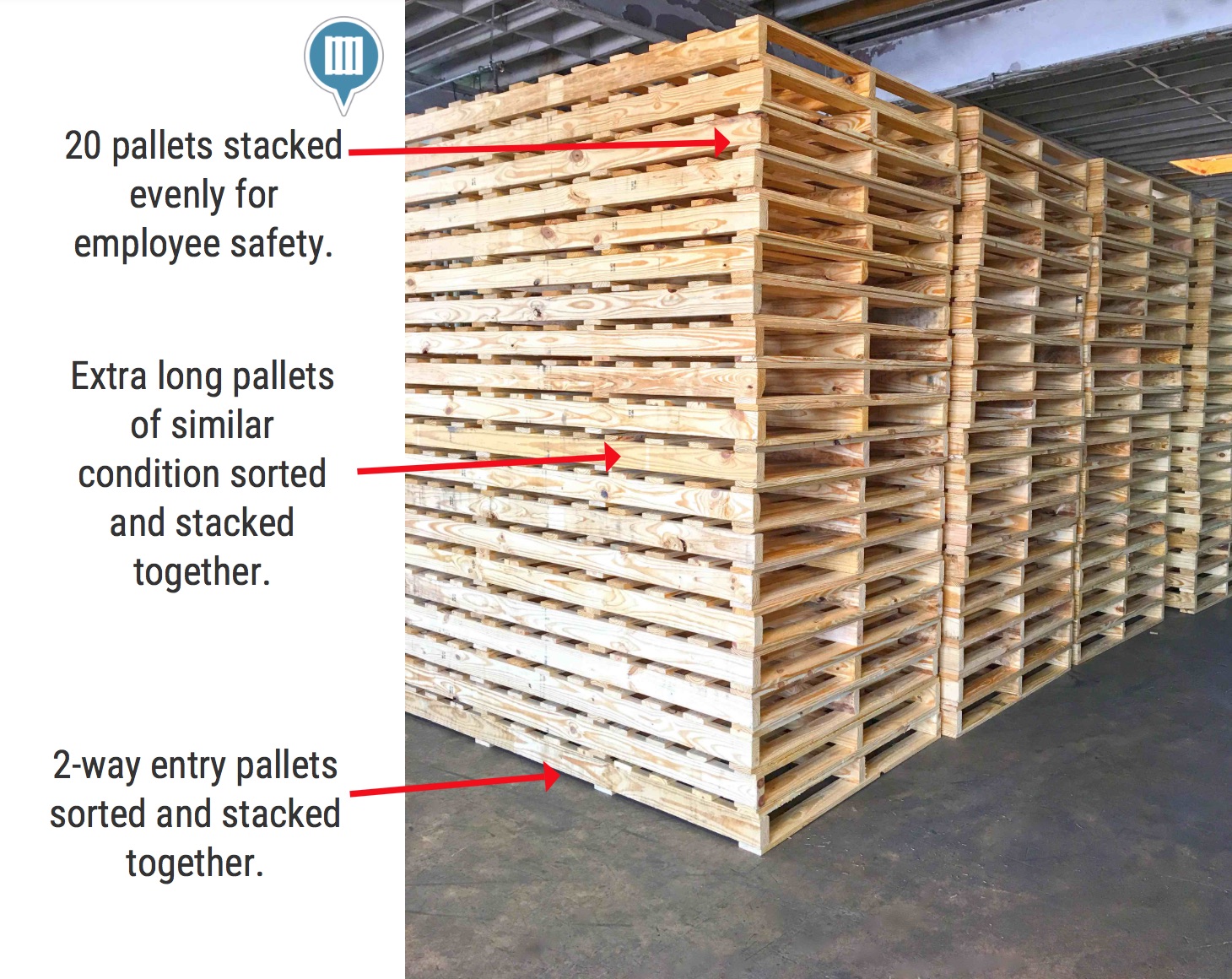

4.

Analysis:

This company has separated pallets by condition as all have bright wood. The pallets are also sorted by type as they are stringer 2-way pallets. The pallets also appear to be staged in a low traffic area. Because the pallets are sorted so well they can stack these pallets 20 high safely.

Recommendation:

This company is stacking, sorting, and grading pallets correctly. Our recommendation is to keep the current operation going smoothly. These pallets are ready to be sold and re-used.

5.

Analysis:

This company does not have many pallets and they are the same size. They are not stacking the pallets correctly, but are leaning them up against a wall. Pallets stacked on the ends and leaning up against a wall can easily fall over.

Recommendation:

This company needs to stack the pallets with the bottom boards on the floor. This company also needs to keep the CHEP pallets separate. If the pallets must go in one stack due to space constraints, then we recommend the CHEP pallets on the bottom and the stringer 48x40-inch pallets on top.

6.

Analysis:

This company has separated pallets by condition as all have bright wood. The pallets are also sorted by type as they are stringer 4-way pallets. The pallets are staged outside, which is not recommended due to the high quality. These pallets are stacked correctly and can go up to 20 high safely.

Recommendation:

This company is stacking, sorting, and grading pallets correctly. We suggest keeping the standard operating procedures. Our only recommendation would be to store the pallets inside if possible to prevent weather damage or theft. This company has a good pallet recycling program.

7.

Analysis:

This company started leaning pallets against a wall. When they had to many they had to then double stack them while leaning them against the wall. This is very dangerous for anyone attempting to move the pallets or walking past. Pallets stacked on the ends and leaning up against a wall can easily fall over. This company is not sorting out the pallets by type. You can see block pallets, stringer pallets both 4-way and 2-way entry, and wing pallets all leaning together. These should be sorted out in separate stacks. It also appears that the pallets are partially blocking the dumpster.

Recommendation:

This company needs to stack the pallets with the bottom boards on the ground. Our recommendation would be to make 2 stacks of pallets 10 high while sorting them as close to the same as possible.

8.

Analysis:

This company is stacking crates of same size and condition together. It appears to be well stacked, however it seems very tall to stack 4 crates.

Recommendation:

Our recommendation would be to make sure these crates are in a low traffic area or stack only 2 high.

9.

Analysis:

This company sorted out pallets by size, but they did not sort our CHEP pallets or sort the pallets by A-Grade and B-Grade. Also the pallets on the top of the stack are crooked and could fall during transport which poses a injury hazard.

Recommendation:

This company needs to continue to sort the pallets by size. Additionally, this company should start a stack of just CHEP pallets. The remaining 48x40-inch pallets should be graded. A-Grade pallets should be in one stack and B-Grade pallets should be in another stack.

10.

Analysis:

This company has separated pallets by condition as all have bright wood and look new or have been used one time. The company has also sorted the pallets by type, as they are all 48x40-inch stringer 4-way pallets. The pallets are staged outside, which is not recommended due to the high quality condition. These pallets are stacked correctly and can go up to 20 high safely. In addition, this company has placed strapping on the pallet stacks to secure them for transport.

Recommendation:

This company is stacking, sorting, and grading pallets correctly. We suggest keeping the standard operating procedures. Our only recommendation would be to store the pallets inside if possible to prevent weather damage or theft.

11.

Analysis:

This company has stacked pallets against a wall in a low traffic area, however, there are single pallets laying on the floor. Pallets laying on the floor are a tripping hazard and should be stacked correctly. This company has the right amount of space to start correct pallet stacks. You can see from the pictures that the stacks started off correctly but then the wrong pallets were placed on top of the stacks and then others sizes and types got mixed in. There are even pallets leaning against other pallets stacks. These leaning pallets are prone to fall over and could injure an employee. The CHEP pallets are also mixed into the pallet stacks and could have easily been sorted. A few plastic pallets are also lying around that could be combined. You can see standard 48x40-inch 4-way pallets, 48x40-inch 2-way pallets, block pallets, wing pallets, and a few other types that could be sorted.

Recommendation:

This company has great storage space for pallets. With a few adjustments this company could have a great pallet management program. We suggest sorting out 48x40-inch 4-way pallets in a stack, 48x40-inch 2-way pallets in a stack, CHEP pallets in a stack, Plastic pallets in a stack, block pallets in a stack, sort out the other types of pallets by size, and make sure no stray pallets are left on the floor.

12.

Analysis:

This company has done a good job of stacking the pallets 10 high. They have sorted out all the block pallets into 2 stacks that can be moved by a pallet jack. Two stringer pallets are mixed into on block pallet stack. These 2 stringer pallets should be placed on top of the stacks instead of in the middle. These pallets are ready for sale and reuse.

Recommendation:

These pallets appear to be in a high traffic area so we suggest not stacking more than 10 high. Moving the pallets with a pallet jack is also easier if the pallets are only 10 high. The stringer pallets should be placed on top of the stack of pallets instead of in the middle. The pallets are in great condition and should be easy to identify lower grade pallets when received.

13.

Analysis:

This company has tossed pallets next to the dock ramp. There is no sorting of pallets or stacking pallets. Additionally, scrap wood and broken pallets are tossed into the pile. Broken pallets can have nails exposed and can be a hazard for employees. Crates are also set around the pile of pallets and scrap wood. This type of pallet management is very poor.

Recommendation:

This company needs to get a container for broken pallets and scrap wood and recycle it at a mulching operation, bio-fuel or wood pellet maker or a DIY wood pallet furniture maker. The pallets in good condition need to be sorted and stacked correctly. The crates need to be stacked in a separate area and by sizes.

14.

Analysis:

This company has stacked block pallets nicely. They have also included banding to keep the pallets from shifting when being moved. A few stringer pallets are at the bottom of the stack which could make removing those difficult if no forklift is available.

Recommendation:

This company needs to continue what they are doing. The pallets are ready for sale and buyers can see exactly what they are getting.

15.

Analysis:

This company uses pallet racks to store pallets which is a great idea. However, the pallets stored in the racks are not stacked correctly. The stacks in the pallet racks are uneven and can shift and fall. This could be very dangerous to employees. In addition to the poor stacking, the pallets are not sorted, so you have to take down multiple pallets to get the size and type that you want. The pallets stacked in front of the pallet racks are equally messy and not sorted by type. A lot of CHEP pallets are mixed into the stacks. The CHEP pallets should always be sorted out.

Recommendation:

This company needs sort out the CHEP pallets. This is half the problem. Once the CHEP pallets are sorted, the company can focus on stacking the pallets evenly. Even stacked pallets will make is safer for employees. Shrink wrapping the stacks of pallets in the pallet rack could be a good thing to do to prevent shifting of the pallets.

16.

Analysis:

This company is maximizing space in the warehouse by using pallet racks to store pallets. This company has sorted pallets by size, type, and condition. These are block pallets and the condition is A-Grade.

Recommendation:

This company has there pallets organized and ready to sell. The only recommendation would be to have a plan for a influx of extra pallets. It looks like they are out of space.

17.

Analysis:

This company is not sorting pallets by size, condition, grade, or type. In this pallet stack there are 2-way pallets, 4-way pallets, A-grade pallets and B-grade pallets. The sizes of the pallets are different and stacking them unevenly is causing problems. There is also strands of shrink wrap that are attached to pallets. These strands of plastic can create a tripping hazard for employees. These pallets are stacked in the middle of high traffic area where other boxes and equipment are being used.

Recommendation:

This company needs to sort the pallets by size, with the largest pallets on the bottom of the stack. We suggest finding a place to store the pallets that is not so crammed. The plastic wrap needs to be removed from all the pallets. The 2-way and 4-way pallets should be grouped together.

18.

Analysis:

This company is stacking pallets correctly. You will notice that the wood of the pallets is very similar. These are B-grade pallets because the wood is darker and not bright. You can also see that all the pallets are 4-way pallets. The pallets are also stacked according to size. Because these 48x40-inch pallets are sorted correctly it is easy to stack them between 18 and 20 high. The pallets are also stored outside. This is ok if they are secured inside a locked fence. However, they should be moved inside as soon as possible to prevent weather damage or bug infestation.

Recommendation:

This company is sorting pallets correctly. We would suggest keeping an eye on the pallets outside to make sure they do not get any more weather damage.

19.

Analysis:

This company is stacking pallets very good but a few things need improvement. The pallets are sorted by size which you can see clearly. You can also see that they have a lot of 48x40-inch 4-way pallets. I doesn’t appear that these pallets are being graded before being stacked together. You can see grey or discolored pallets mixed in with the bright wood pallets. The company is not sorting out block pallets. There are a few block pallets mixed into the stacks. The pallets are stacked evenly and stacks are 18 to 20 high. The pallets are stored outside in what appears to be a low traffic area.

Recommendation:

This company is sorting pallets by size correctly. Next steps would be to sort out the block pallets. Additionally, sorting the 48x40-inch 4-way pallets by grade would improve this pallet management program. We would suggest keeping an eye on the pallets outside to make sure they do not get any more weather damage.

20.

Analysis:

This company is sorting pallets by size, type, and grade. All of the pallets on the left are 48x40-inch (size) 4-way pallets (type). Because they are all the same this company stacked them to 40 high. This is not recommended for safety reasons. Strong wind or accident could knock the pallets over. The grade of the pallets appears to be B-grade due to the slight discoloration. CHEP pallets are also sorted away from the standard sized pallets.

Recommendation:

This company is doing a great job of sorting by size, type, and grade. Our recommendation would be to not stack the pallets so high. Pallets should be stacked in low traffic areas around 20 high. Also with so many pallets sitting outside, weather damage is a concern. Using a 53-foot trailer to store the pallets in may be an option.

21.

Analysis:

This company has sorted some pallets by size, type, and condition but has left some other pallets in disarray. The larger pallets on the right are correctly stacked and are banded to secure the stack. The pallets to the left are plastic pallets and don’t appear to be stacked very well, and may be mixed with cardboard and pressed wood pallets. In the stack of pallets furthest to the left you can see larger pallets on top of the pallet stack. This can be a hazard for employees. If that stack were to fall and hit an employees injury could occur.

Recommendation:

This company was on the right track with stacking pallets but something happened. Maybe a new employee was not trained properly. The stack of pallets on the left needs a complete overhaul with sorting by size and type and condition, grading, and re-stacking.

22.

Analysis:

This company has a pallet staging area that has low employee traffic. Some pallets are stacked but not by size, type, or grade. There are also several piles of broken pallets and pallet wood. This pile is a complete hazard. There is a large oversized custom pallet that is leaning against the scrap wood pallets. Removing this pallet is a hazard.

Recommendation:

This company has a good pallet staging area but needs to get a container for the scrap wood and broken pallets and needs to sort the pallets correctly. There are many standard pallet sizes and 48x40-inch pallets in the mix. Those can be sorted out and listed as pallets for sale.

23.

Analysis:

This company has a pallet staging area that has low employee traffic but is located by a roll up dock door. The pallets are stacked very low due to the mixing in of damaged pallets that make pallet stacks unstable. The pallet stacks are shrink-wrapped which would be good if the pallets were stacked correctly. Block pallets are mixed with stringer pallets and odd sizes. The main problem we see here is all of the damaged pallets mixed in with the good pallets.

Recommendation:

This company needs to separate the damaged pallets first. Second they should sort the pallets by type, block or stringer. Next they should stack the pallets 10 high. The company can continue to shrink-wrap the pallets.

24.

Analysis:

This company has a few mixed sized pallets in there stacks. Some of the pallets are of different condition. The company is stacking smaller pallets on top of larger pallets, which is ok because space seems limited. The company is sorting the wing pallets out and stacking them together.

Recommendation:

This company is doing an OK job considering the small amount of pallets they have. We would suggest that the company continue to sort pallets.

25.

Analysis:

This company has placed a smaller pallet under a longer pallet. This can create a tripping hazard. This company also has a pallet that needs repair.

Recommendation:

This company is doing an OK job considering the small amount of pallets they have. We would suggest that the company sends in the broken pallets in for repair.

26.

Analysis:

This company is stacking pallets very high in a high employee traffic area next to a door. Pallets stacked more than 30 high are a risk for tipping over. The pallets are sorted by size but they should be sorted by type such as CHEP pallets and standard size pallets 48x40-inch 4-way pallets.

Recommendation:

This company has good pallets and with a little work they can have a great program. CHEP pallets should be sorted and stacked together. The PECO pallets can be placed with the few other 2-way 48x40-inch pallets. The standard size pallets can all be stacked the same way.